The 21st century has been hailed as the century of innovation with the recent technology of 3D printing spearheading this growth and I believe that most of us from the computer aided-design world must have heard of the possibilities that 3D printing has to offer both designers and manufacturers.

3D printing also known as additive manufacturing has also been labeled as a disruptive technology due to the fact that every Tom, Dick and Harry can simply purchase a domestic 3D printer and produce almost any item he or she desires from the comfort of their homes.

Which leads us to the question of what does the process of 3D printing entail?

There are basically 3 phases or stages that must be undergone before you can print your favorite furniture, fictional character or unique ideas and these phases are:

The Design Phase: before a 3D printer prints, it needs to be fed a 3 dimensional model of the particular item you plan to print and one can get this 3D model by simply scanning the item with a 3D printer or by modeling a 3D character with the aid of CAD software application. And while 3D scanners may be viewed as a simpler way of getting the needed models, the use of CAD provides a more detailed model thereby increasing the real-life feel of that model.

The Assembling Phase: This covers the all the processes involved in assembling the needed materials—printing feed, ink etc.—that will be used in the manufacturing phase.

The Assembling Phase: This covers the all the processes involved in assembling the needed materials—printing feed, ink etc.—that will be used in the manufacturing phase.

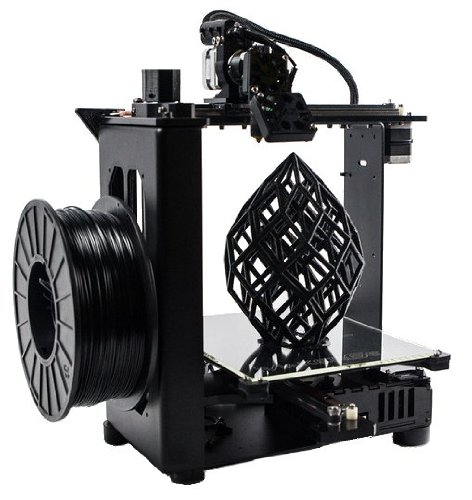

The Manufacturing Phase: This final stage consists of using a 3D printer to produce a life-like representation of your chosen item.

Focusing on the initial stage—the design phase—the advantages of using CAD software applications in creating models are numerous and these advantages include the following parameters:

Accuracy: computer aided-design software applications are generally known for their intuitive workspaces which support the use of accurate dimensions, materials and techniques for designing accurate 3D representations. This accuracy is then transferred to a 3D printer for the manufacturing phase.

Realistic Representations: When printing an item such as toys, action figures etc. that depends on its accuracy—in terms of looks—for its success, the need for feeding life-like 3D characters to a printer cannot be overstated and this accuracy can only be gotten with the use of CAD tools that can render perfect looking models.

Troubleshooting Design Issues: to minimize waste when printing an item, the designer needs to carry out different analysis and tests on the compatibility of the item to be printed. This analysis can be done on CAD software applications such as AutoCAD, Maya, Microstation and Solid works. These tests which cost nothing except time drastically reduce the capital, human resources and time that will be wasted if the manufacturing phase is initiated without carrying out any test analysis.

Forestalling Copyright Infringement: with the advent of 3D printing more companies are now safe-guarding their creative ideas with the use of copyright laws therefore, the printing and sale of popular cartoon, film and fictional characters now come with stiff penalties. So designing your own unique characters or getting a CAD user to help you with design is your best bet for avoiding copyright infringements.