If you’re something of a craft enthusiast, you may well have come across a CNC (Computer Numerical Control) router, which is a computer-controlled cutting machine that can be used across a variety of materials and projects.

However, what you may not know is that there are various types of CNC machines on the market, each of which has its own unique application and levels of demand within specific industries.

We’ve outlined the five main types of CNC cutting machines below while asking how they’re used and the type of applications that they commonly work on.

#1. CNC Milling Machines

We’ll start with what is arguably the single most popular type of CNC machine, and one that can be used to cut a large and diverse range of materials.

More specifically, CNC milling machines can be used to create shapes, slots, holes, notches, grooves, pockets and specialty faces, while performing the fundamental machining process of manufacturing CNC milling parts.

With this type of machinery, mills can translate specific computer programs that comprise both numbers and letters, each of which can be used to move the spindle in various different ways to create alternative cuts and outcomes.

Most mills utilize what is known as the ‘G-Code’, which is a standardized programming language that’s recognized by the majority of CNC machines.

Interestingly, a CNC mill is very large when compared with other, similar tools, and can be quite costly too. Some of the biggest and most popular CNC milling manufacturers include HAAS, DMG Mori and Okuma.

#2. CNC Lathes

Next up are CNC lathes, which are typically used to manufacture cylindrical objects and perform the process of producing CNC turning parts.

In practical terms, this functions by cutting workpieces as they’re rotated, with lathes utilizing a tool to shape the workpiece while the material block turns rapidly on a spindle.

Because of their mode of operation, CNC lathes can make precise cuts quickly and efficiently, while they’re particularly accurate when compared to manual lathes. To this end, they often have fewer axis than CNC milling machines, making them smaller, more compact, and preferable when completing smaller projects.

However, CNC lathes come with similar controls to those of mills and are also capable of reading G-Code along with a raft of alternative proprietary languages.

HAAS, DMG Mori, and Okuma also manufacture CNC lathes, mainly because the basic framework of these cutters is similar to manual alternatives.

#3. CNC Drilling Machines

Third on our list is CNC drilling machines, which boast a relatively limited clear-defined purpose when compared to alternative tools.

More specifically, CNC drilling machines are used to drill holes in the workpiece, while they’re also used to locate the precise position for drilling accurately and in no time at all.

More sophisticated product iterations can also perform reaming, counterboring, and tapping holes, but the capacity of your drilling machines will depend on your underlying budget and how much you’re willing to spend in the marketplace.

#4. CNC Plasma Cutters

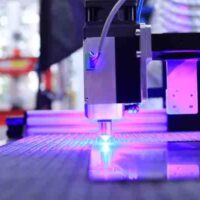

The process of plasma cutting is a little more advanced and sophisticated, as it involves the manipulation of various materials using a plasma torch.

This method is most commonly used to cut heavy materials, including steel and a diverse array of other robust metals.

When using a CNC plasma cutter, gas is blown out at an incredibly high speed from a nozzle. Whilst this process is continuing, an electrical arc forms through the gas that’s produced, directly onto the surface or material that’s being cut.

This then converts some of the excess gas into plasma, with temperatures ranging from 10,000 to 15,000 degrees depending on your precise application and the machine that you use.

As you can imagine, the plasma produced by this type of machine is hot enough to melt whatever material is being cut, while it also blows away any molten metal from the site.

In terms of their shape and size, CNC plasma cutters are incredibly similar to CNC routers, as they work solely with two-dimensional shapes and are typically used to cut and process metal.

#5. CNC Grinders

We close our list with a so-called “CNC grinder”, which is categorized as a precision performance tool that utilizes a rotating wheel at the core of its functionality.

This rotary wheel is used to abrade a particular material by grinding or grating it into a desired shape, and as a result of this, it’s largely considered to be much easier to use than milling machines or CNC lathes.

It’s also a relatively safe tool, as it makes incremental cuts into the material and typically cuts mass away from the metal in question.

Make no mistake; manual machining and cutting metal can be a tough and time-consuming task, but tools such as CNC grinders allow you to work far more efficiently and to a much higher standard over an extended period of time.

The computerised element of a CNC grinder is key in this aspect, with this tool widely used by amateurs and professionals to complete complex tasks quicker and maintain a more consistent standard of work and finish.

CNC grinders also use and comprehensive G-code, meaning that you can use them to complete a diverse array of simple and complicated cuts as required.

Want to read more of our posts about CNC Machining? Check out these advantages of integrating CAD to CNC Machining.